Call : 07971258133

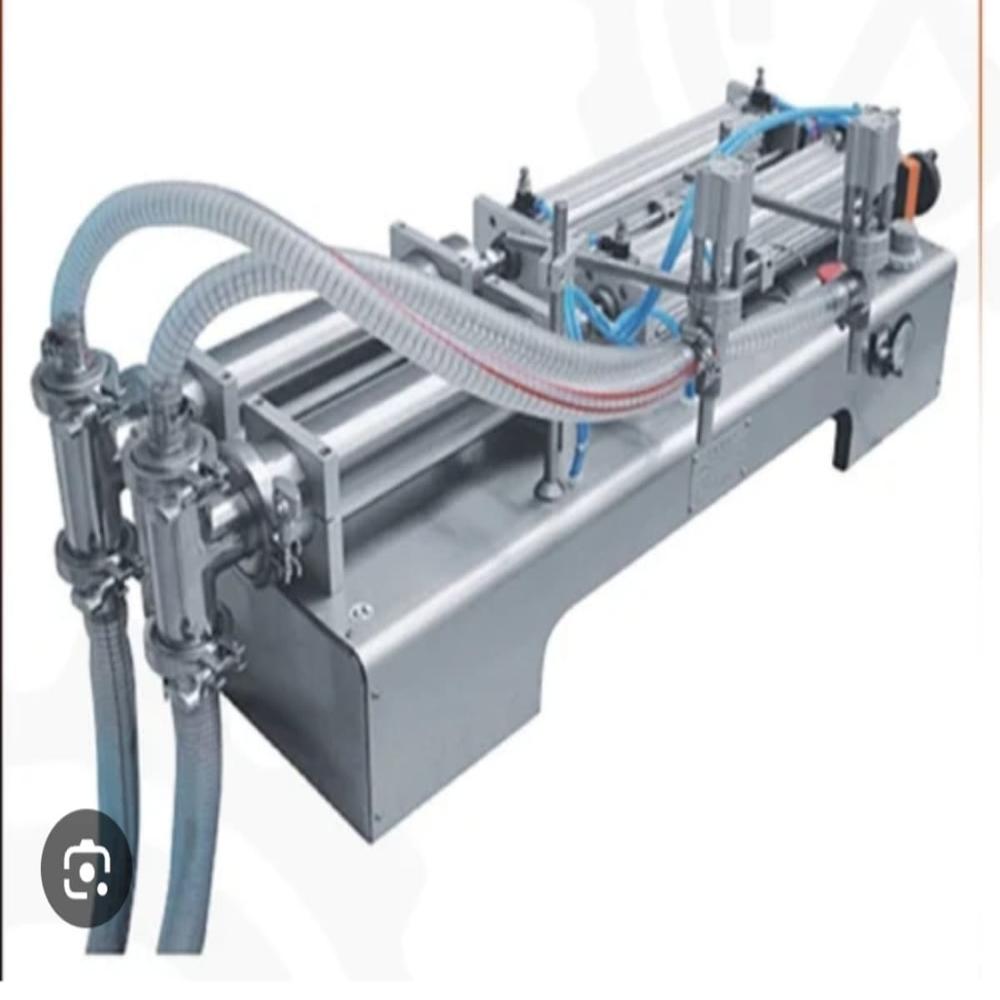

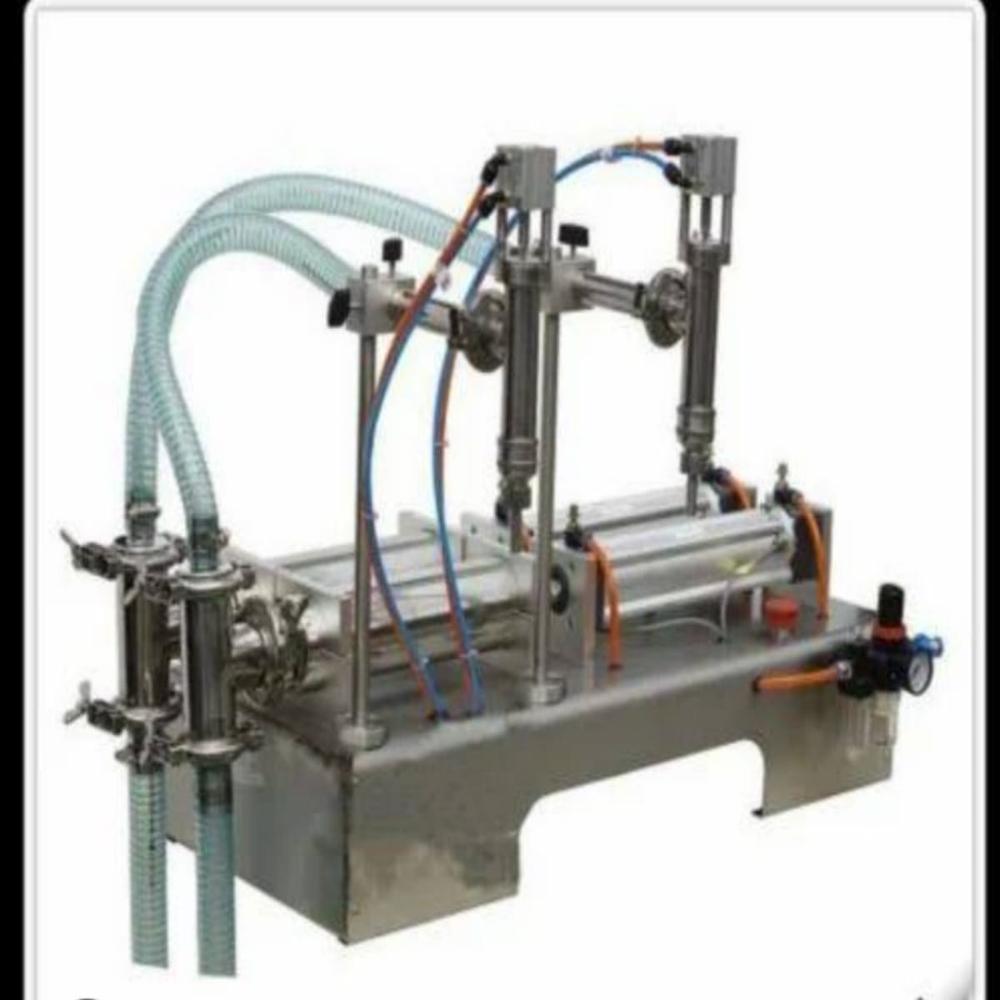

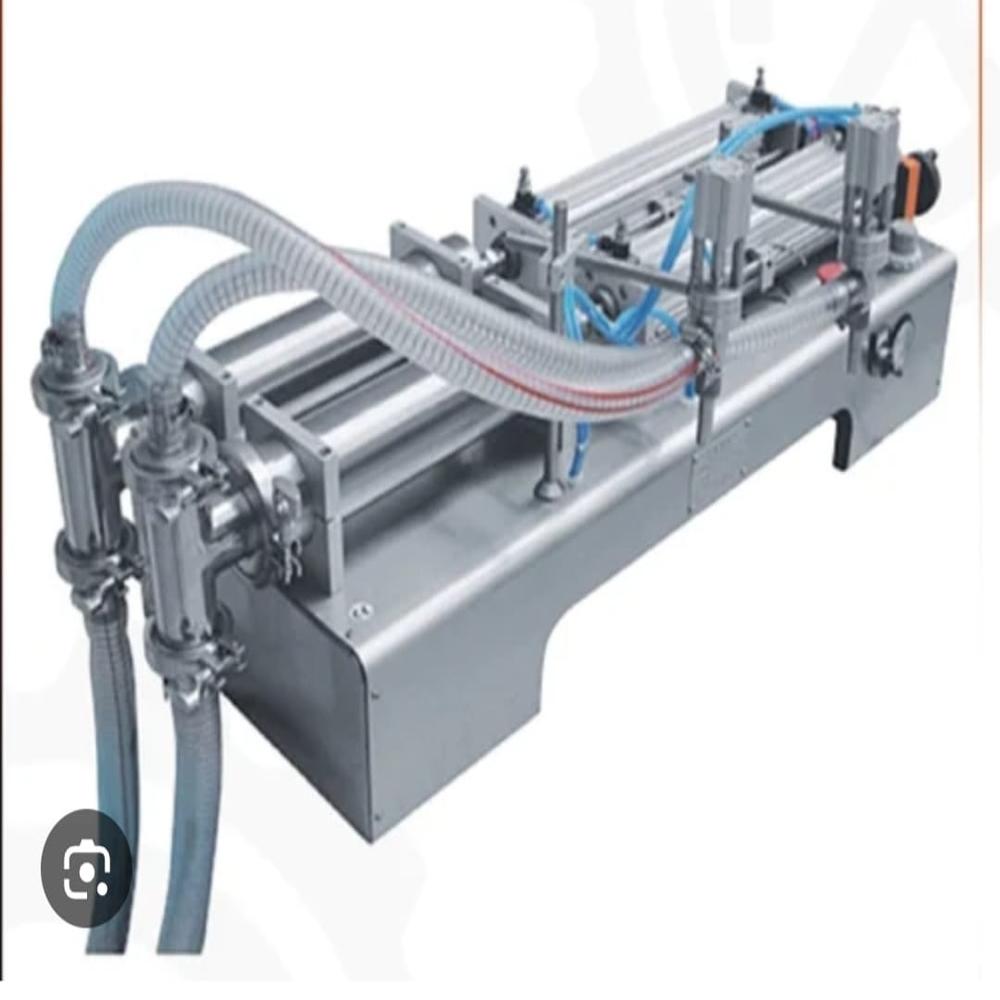

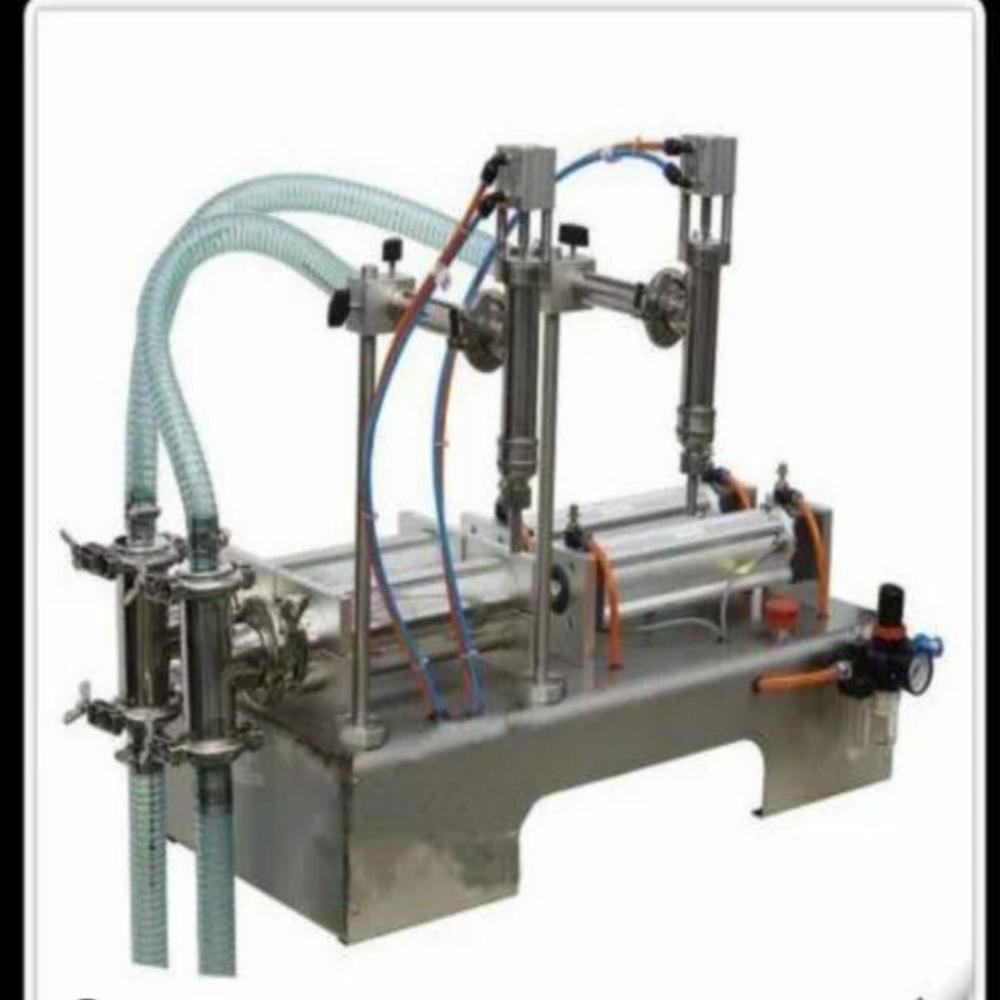

SEMI AUTOMATIC DOUBLE HEAD LIQUID FILLING MACHINE

42000.0 INR/Piece

Product Details:

X

SEMI AUTOMATIC DOUBLE HEAD LIQUID FILLING MACHINE Price And Quantity

- 42000.0 INR/Piece

- 1 Piece

SEMI AUTOMATIC DOUBLE HEAD LIQUID FILLING MACHINE Trade Information

- Cash on Delivery (COD)

- 1 Piece Per Week

- 1 Week

- Yes

- ALL TYPES OF OILS AND LIQUID FILLING MACHINE

- Asia

- All India

Product Description

Specifications

Brand: Generic (Imported)

Weight (Approx.) : 70 kg

Body Material : Stainless Steel

Power source : 220V/110V

Power : 10W

Phase : Single

Frequency : 50Hz

Filling Head : Double Head

Filling Volume : 100-1000 ml

Hopper Capacity : 20 liter

Air Supply : 400 LPM (both nozzle)

Air Pressure : 0.6 Mpa (both nozzle)

Efficiency : 600-1500 bottles per hr

Note : Compressor required extra

Description

This machine is the semiautomatic piston type liquid filling machine This machine is reasonable in design, small and exquisite in the model. The piston and hopper of the cylinder are made up of 304 stainless steel and Polytetrafluoroethylene (PTEF). Both filling volume and filling speed can be adjusted at will, filling accuracy is high. Filling head adopts anti-leakage and lifting filling device.

Features

:

Suitable for liquid filling

Small model easy to handle

High accuracy

Filling volume and filling speed can adjust

Applications

:

Pharmaceutical Industry : It is utilized for filling medicinal liquids, syrups, and other pharmaceutical products into vials or bottles, which is in low viscosity just like water.

Food and Beverage Industry : This machine is widely used for filling liquids such as free flow liquid into bottles or containers ranging from 100 ml to 1000 ml. Its precision ensures consistent fill levels, which is crucial for product quality and compliance with regulations.

Cosmetic Industry : Digital free flow liquid filling machines are used to fill free flow liquid like Rose Water. Their precise control over the filling volume helps maintain product consistency.

Laboratories : Useful for precise filling of liquid samples and solutions.

Usage

:

1. Preparation :

Ensure the machine is clean and free from any previous product residues.

Set up the machine on a stable surface and connect it to a power source.

2. Adjusting the Settings :

Set the desired filling volume (between 100-1000 ml) using the volume adjustment knob.

3. Container Placement :

Place empty containers under the nozzles in a manner that allows for easy filling.

Ensure that all containers are aligned properly to avoid spills.

4. Filling Process :

Activate the filling process by pressing the foot pedal.

Monitor the filling to ensure that each container receives the correct amount of liquid.

5. Post-Filling :

Once filling is complete, remove filled containers from beneath the nozzle.

Clean any spills around the filling area to maintain hygiene.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Liquid Filling Machine' category

|

Worship Packaging LLP

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese