MANUAL PASTE FILLING MACHINE

Price 12000.0 INR/ Piece

MANUAL PASTE FILLING MACHINE Specification

- Product Type

- Paste Filling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Manual

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

MANUAL PASTE FILLING MACHINE Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Packaging Details

- ALL TYPES OF PASTE FILLING MACHINE

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About MANUAL PASTE FILLING MACHINE

Specifications

- Brand: Generic (Imported)

- Weight (Approx.) : 9.3 kg

- Material:Stainless Steel

- Temperature:Up to 200 Celsius (This likely refers to the materials temperature compatibility,notthe machines operating temperature, as its manually operated and air-cooled)

- Frequency:50/60Hz (This specification seems irrelevant as the machine is manually operated and doesnt use electrical frequency)

- Deviation:2% (Filling accuracy)

- Hopper Capacity:10 Liters (Approximate)

- Nozzle Diameter:2.5 mm

- Cooling by:Air cooling (This likely refers to the machine not having active cooling components, as its manually operated)

- Operation Mode:Manual

- Color:White (color may vary)

- Filling Range:5-50 ml

- Dimension (L x W x H):270 x 270 x 710 mm

Description

Features

:- Manual Operation:Simple and direct control over the filling process.

- Adjustable Filling Volume:Precisely dispenses volumes from 5 to 50 ml.

- Stainless Steel Construction:Ensures durability, hygiene, and corrosion resistance.

- Compact and Portable:Small footprint and lightweight design for easy relocation.

- 10 Liter Hopper:Provides a decent capacity for manual filling tasks.

- Single Filling Nozzle:With a 2.5 mm diameter for controlled dispensing.

- 2% Filling Accuracy:Offers relatively consistent volume dispensing.

- No Power Required:Operates without electricity, enhancing portability.

Applications

:This manual filling machine is suitable for a range of low to medium viscosity liquids and pastes in industries such as:

- Cosmetics:Filling essential oils, lotions, creams, gels, lip gloss, small samples, etc.

- Pharmaceuticals:Dispensing small volumes of liquid or semi-liquid medications, ointments.

- Food & Beverage:Filling small quantities of sauces, honey, jams, flavorings.

- Chemicals:Dispensing small amounts of certain non-corrosive liquids.

- Laboratories:For dispensing precise volumes in experimental or small-scale production.

Usage

:- Setup:Place the machine on a stable and level surface. Ensure all parts are clean and properly assembled.

- Material Loading:Pour the liquid or paste into the 10-liter hopper. Ensure the material is free of large particles that could block the nozzle or piston.

- Volume Adjustment:Adjust the filling volume using the adjustment screw or mechanism on the machine to the desired quantity between 5 and 50 ml.This typically controls the stroke length of the piston.

- Container Placement:Position the empty container under the filling nozzle.

- Manual Operation:Operate the handle or lever to draw the product from the hopper into the cylinder and then dispense it into the container. The piston movement controls the filling volume.

- Repeat:Continue placing empty containers and operating the handle until all desired containers are filled.

- Cleaning:After use, disassemble and thoroughly clean all parts that came into contact with the product using appropriate cleaning solutions. Ensure all residue is removed.

Maintenance:

Proper maintenance will ensure the longevity and accurate operation of the machine:

- Daily Cleaning:After each use, disassemble and clean the hopper, cylinder, piston, and nozzle thoroughly with suitable cleaning agents. Rinse and dry all parts before reassembly.

- Regular Inspection:Periodically inspect all components for any signs of wear, damage, or loose connections. Tighten any loose screws or fittings.

- Lubrication:Lubricate the moving parts, such as the piston rod and any joints, with food-grade or appropriate lubricant as recommended by the manufacturer or as needed to ensure smooth operation.

- Seal Maintenance:Check the piston seals regularly for wear or damage. Replace them if they are worn or cracked to prevent leaks and maintain filling accuracy.

- Nozzle Cleaning:Ensure the nozzle remains free of blockages. Clean it regularly, especially if filling viscous materials.

- Storage:When not in use, clean the machine thoroughly and store it in a clean, dry place.

Precautionary Guidance:

- Read Instructions:Carefully read and understand the operating instructions provided by the manufacturer before using the machine.

- Material Compatibility:Ensure the filling material is compatible with the stainless steel components of the machine. Avoid filling highly corrosive substances that could damage the material.

- Temperature Limits:While the specification mentions 200 Celsius, this likely refers to the temperature thematerialbeing filled can withstand. The machine itself is manually operated and air-cooled; avoid using it to fill extremely hot materials that could pose a safety risk.

- Proper Assembly:Ensure all parts are correctly assembled before operation to prevent malfunctions or damage.

- Gentle Operation:Operate the handle smoothly and avoid applying excessive force.

- Cleaning Procedures:Use appropriate cleaning solutions and ensure they are thoroughly rinsed off to prevent contamination of subsequent fillings.

- No Electrical Hazards:As this is a manual machine, there are no direct electrical hazards associated with its operation. However, ensure the surrounding environment is safe.

- Maintenance Schedule:Adhere to a regular maintenance schedule to ensure the machine operates efficiently and reliably.

Durable and Eco-Friendly Design

Manufactured using premium stainless steel, this paste filling machine promises durability and ease of cleaning. Its eco-friendly construction aligns with modern sustainability standards, minimizing environmental impact while maintaining high performance.

Versatile Applications in Viscous Filling

This machine is perfect for filling various pastes, from food to industrial products. The semi-automatic operation provides more flexibility to match diverse production requirements, making it suitable for dealers, suppliers, and fabricators.

User-Friendly Interface with Reliable Warranty

The integrated Human Machine Interface simplifies operation, ensuring intuitive controls for enhanced productivity. With a one-year warranty, users can trust in consistent performance and reliable after-sales support.

FAQs of MANUAL PASTE FILLING MACHINE:

Q: How does the manual paste filling machine operate?

A: This machine uses a semi-automatic mechanism with an electric drive. The operator controls the filling process via an easy-to-use Human Machine Interface, making it straightforward to fill viscous materials.Q: What materials can be filled using this machine?

A: The machine is designed to fill viscous pastes, such as sauces, creams, gels, and similar substances. Its stainless steel construction makes it suitable for food-grade and industrial applications.Q: When should I consider using this paste filling machine for my business?

A: If your operations require reliable, hygienic, and efficient filling of viscous products on a moderate scale, this machine is an excellent choice, especially for manufacturers, distributors, and fabricators.Q: Where is this machine commonly used or available?

A: This manual paste filling machine is widely used by producers, wholesalers, retailers, and traders across India. Its available through dealers, suppliers, and fabricators nationwide.Q: What is the process of cleaning and maintaining the machine?

A: The stainless steel build ensures easy cleaning and corrosion resistance. Regular maintenance involves simple disassembly for thorough sanitation and periodic checks of electric and interface components.Q: How is the machine beneficial for eco-friendly production?

A: The machine is engineered with eco-friendliness in mind, minimizing waste during filling processes and using energy efficiently, supporting businesses sustainable operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

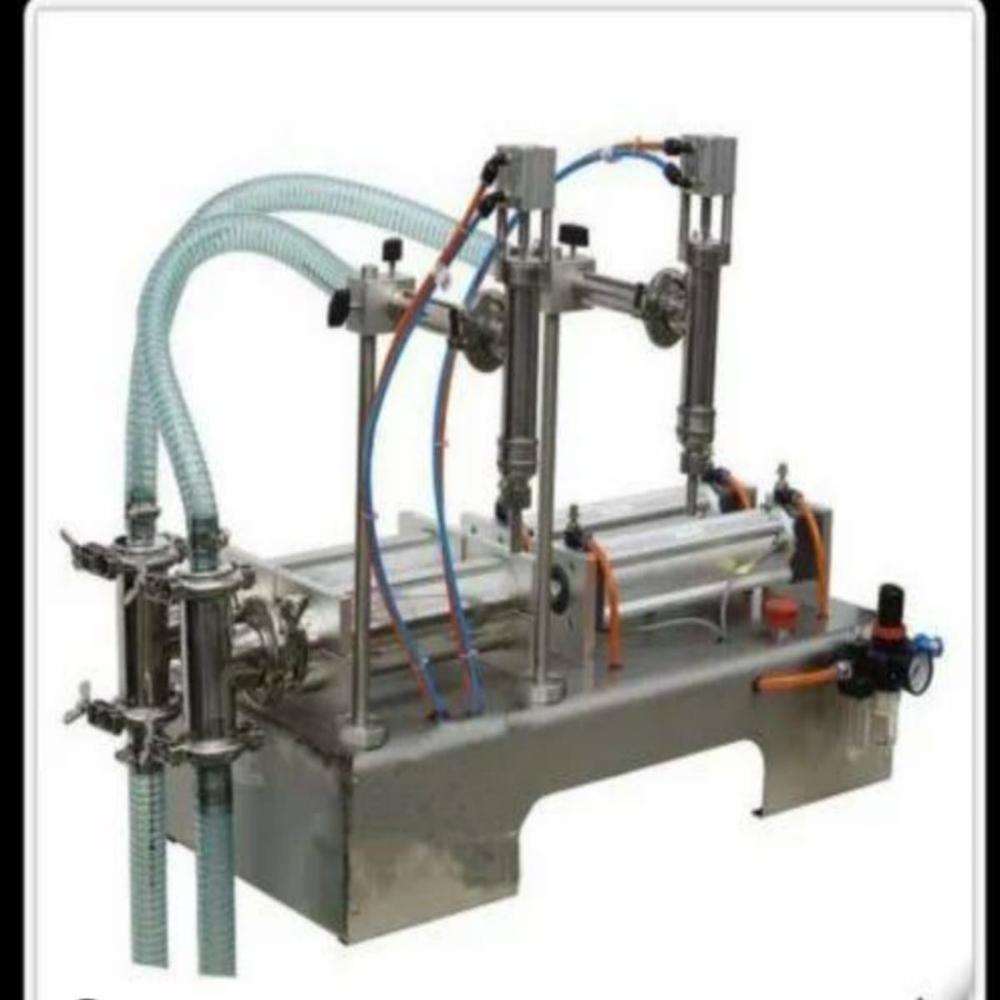

SEMI AUTOMATIC DOUBLE HEAD LIQUID FILLING MACHINE

Price 42000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Feature : ECO Friendly

Product Type : Liquid Filling Machine

Computerized : No

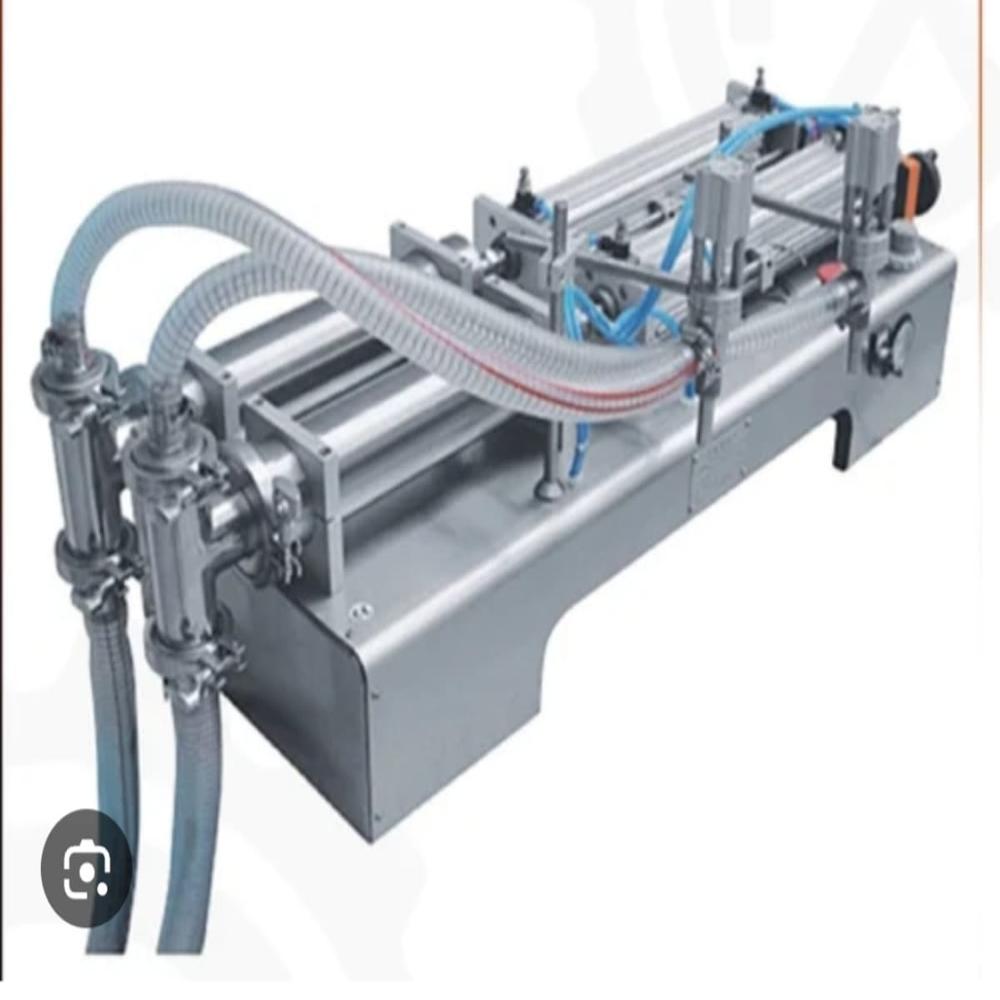

SEMI AUTOMATIC DOUBLE HEAD PASTE FILLING MACHINE

Price 42300.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Feature : ECO Friendly

Product Type : Paste Filling Machine

Computerized : No

SEMI AUTOMATIC PASTE FILLING MACHINE

Price 32500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Feature : ECO Friendly

Product Type : Paste Filling Machine

Computerized : No

SEMI AUTOMATIC DOUBLE HEAD LIQUID FILLING MACHINE

Price 42000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Feature : ECO Friendly

Product Type : Liquid Filling Machine

Computerized : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese