SEMI AUTOMATIC LIQUID FILLING MACHINE

Price 30000.0 INR/ Piece

SEMI AUTOMATIC LIQUID FILLING MACHINE Specification

- Product Type

- Liquid Filling Machine

- Material

- DD

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

SEMI AUTOMATIC LIQUID FILLING MACHINE Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Packaging Details

- ALL TYPES OF OIL AND LIQUID FILLING MACHINE .

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About SEMI AUTOMATIC LIQUID FILLING MACHINE

Specifications

- Brand: Generic (Imported)

- Weight (Approx.) : 30 kg

- Body Material : Stainless Steel

- Power source : 220V/110V

- Phase : Single

- Frequency : 50Hz

- Filling Head : Single Head

- Filling Volume : 10-100 ml

- Air Supply : 400 LPM

- Air Pressure : 0.6 Mpa

- Efficiency : 600 bottles per hr

Description

Features

:- Filling Range :Capable of filling liquids in the range of 10 to 100 ml.

- Semi-Automatic Operation :Requires manual intervention for certain processes while automating the filling process.

- Single Nozzle Design :Equipped with one nozzle for precise filling, suitable for small batch production.

- Durable Construction :Made from high-quality materials to ensure longevity and resistance to corrosion, especially when handling various liquids.

Applications

:- Cosmetic Industry :Digital free flow liquid filling machines are used to fill free flow liquid like Rose Water. Their precise control over the filling volume helps maintain product consistency.

- Laboratories :Useful for precise filling of liquid samples and solutions.

- Pharmaceutical Industry :It is utilized for filling medicinal liquids, syrups, and other pharmaceutical products into vials or bottles, which is in low viscosity just like water.

- Food and Beverage Industry :This machine is widely used for filling liquids such as free flow liquid into bottles or containers ranging from 10 ml to 100 ml. Its precision ensures consistent fill levels, which is crucial for product quality and compliance with regulations.

Usage

:- Ensure the machine is clean and free from any previous product residues.

- Set up the machine on a stable surface and connect it to a power source.

- Set the desired filling volume (between 10-100 ml) using the volume adjustment knob.

- Place empty containers under the nozzle in a manner that allows for easy filling.

- Ensure that all containers are aligned properly to avoid spills.

- Activate the filling process by pressing the foot pedal.

- Monitor the filling to ensure that each container receives the correct amount of liquid.

- Once filling is complete, remove filled containers from beneath the nozzle.

- Clean any spills around the filling area to maintain hygiene.

Efficient Semi-Automatic Filling Solution

The Semi Automatic Liquid Filling Machine provides a user-friendly experience with its Human Machine Interface, allowing seamless control over filling processes. Its electric drive ensures consistent results, while DD material enhances longevity. Eco-friendly features make it a responsible choice for modern businesses.

Versatile Applications Across Industries

Whether you are a dealer, manufacturer, supplier, or wholesaler, this liquid filling machine adapts to various commercial needs. Ideal for fabricators and producers as well, its semi-automatic operation enhances flexibility and supports different liquid products efficiently. Distributed widely across India.

FAQs of SEMI AUTOMATIC LIQUID FILLING MACHINE:

Q: How does the semi-automatic liquid filling machine operate?

A: The machine is operated through a Human Machine Interface, allowing the user to control filling volumes and cycles precisely. The semi-automatic grade requires operator involvement for loading and positioning containers, while the electric drive manages the actual filling process.Q: What types of businesses can benefit from using this liquid filling machine?

A: This machine is suitable for a wide range of businesses, including dealers, distributors, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers in India. Its versatility allows adaptation to various liquid products.Q: When is maintenance required for the semi-automatic liquid filling machine?

A: Routine maintenance is suggested at regular intervals to optimize performance. Additionally, users can rely on the included one-year warranty for any necessary repairs or technical support during the first year of operation.Q: Where is this machine typically used within the industry?

A: It is commonly found in manufacturing plants, production lines, packaging facilities, and retail operations across India, where efficient liquid filling is needed for products such as beverages, chemicals, and pharmaceuticals.Q: What is the process of setting up and using the liquid filling machine?

A: After installation, users configure the filling parameters using the Human Machine Interface. Operators sequentially place containers under the filling nozzle and activate the filling cycle, ensuring accuracy and minimal waste.Q: How does the eco-friendly feature benefit businesses?

A: The machines eco-friendly design reduces energy consumption and limits waste during the filling process. Businesses benefit by lowering operational costs and contributing to environmental sustainability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

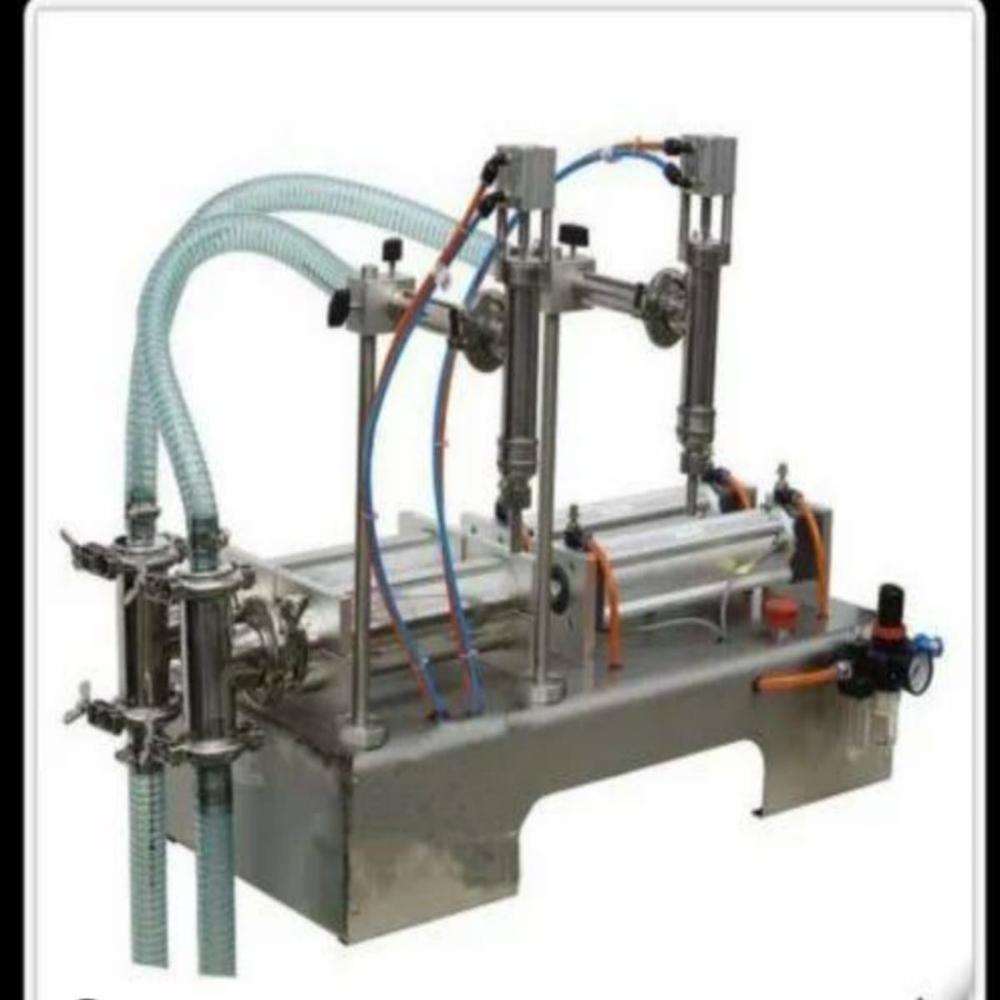

SEMI AUTOMATIC DOUBLE HEAD LIQUID FILLING MACHINE

Price 42000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Product Type : Liquid Filling Machine

Computerized : No

Control System : Human Machine Interface

SEMI AUTOMATIC PASTE FILLING MACHINE

Price 32000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Product Type : Filling Machine

Computerized : No

Control System : Human Machine Interface

DOUBLE HEAD DIGITL LIQUID FILLING MACHINE

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Product Type : LIQUID FILLING MACHINE

Computerized : Yes

Control System : Human Machine Interface

MANUAL PASTE FILLING MACHINE AO3

Price 12500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Product Type : Paste Filling Machine

Computerized : No

Control System : Human Machine Interface

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese